O-rings and rubber seals

Custom-made or standard types

Seals are one of Betech's core areas of expertise, and we dare to say that whatever your needs, we can find a seal that will do the job - whether it's static or dynamic.

The popular O-ring is both the easiest and most versatile rubber seal - used either alone or in conjunction with other types of seals.

Static and dynamic seals

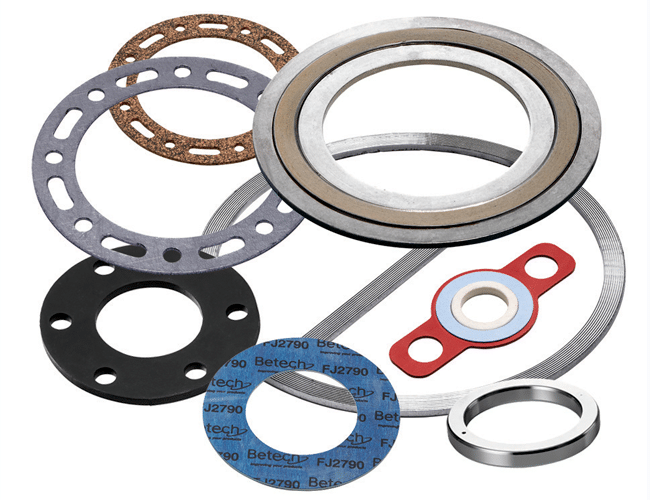

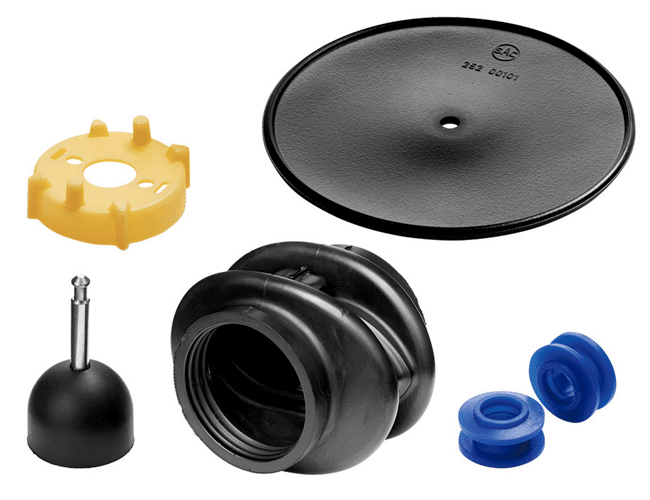

We supply seals in many types, materials and dimensions.

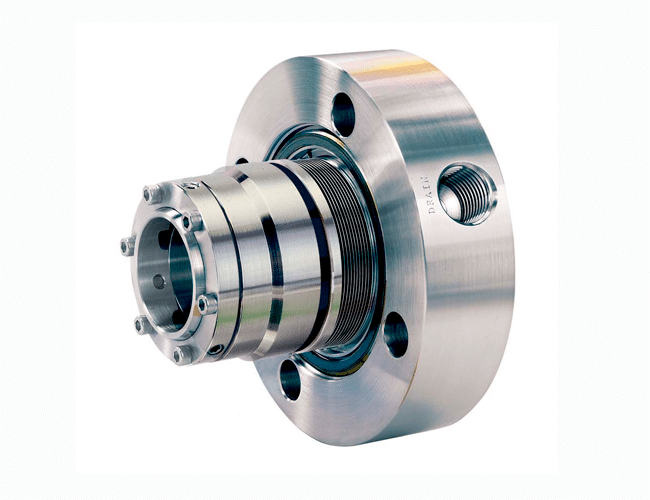

In addition to standard types, Betech offers individually designed seals with special installation dimensions, as well as spring-activated special seals and other specialized solutions for demanding applications:

- O-rings, D-rings and X-rings

- Clamp gaskets

- Bonded Seals

- Oil seals and V-rings

- Activated PTFE seals

- Braided gaskets and mechanical shaft seals

- Hydraulic and pneumatic seals

Get security of supply with a storage agreement

If your business needs a certain amount of seals on a regular basis, you can enter into a stock agreement with Betech. This ensures that a minimum stock is always available and provides you with security of supply for critical productions or urgent tasks.

Get design and construction advice

Consult us in the design phase. We put our many years of experience at your disposal and are happy to enter into a close dialog about the optimal sealing solution for your specific application.

In addition to consulting, we custom design and manufacture solutions from our extensive range of compounds and packaging materials.

O-rings and X-rings - the easy and versatile seals

O-rings are the world's most widely used type of seal thanks to their simple shape and the small space they require. They are easy to install and come in countless materials and dimensions. This means that regardless of operating conditions and installation dimensions, you can find an O-ring that meets the requirements of your application. Therefore, the O-ring has a very wide range of applications in all branches of the technical industry.

Why is the O-ring so popular?

There are several good reasons why the O-ring has become the most widely used seal type:

- The O-ring is a simple and inexpensive solution compared to other types of seals

- The O-ring can be used as a double-acting, compressible seal in both static and dynamic applications

- The O-ring is easy to install as it can withstand both compression and stretching

- The O-ring groove is simple to manufacture

- The O-ring can usually be installed without the use of tools

How the O-ring works

When the O-ring is subjected to tension and pressure, its shape changes, filling the O-ring groove and splitting. This creates a tight seal that prevents the passage of liquids, gases and contaminant particles.

X-rings provide less friction than O-rings. Where the O-ring is made from a solid rubber cord, the X-ring has an X-shaped cross-section. X-rings are more widely used in dynamic applications where you want lower friction.

O-rings and X-rings can be supplied surface-treated if you want to reduce friction, e.g. for automatic assembly.

The O-ring can be used in both static and dynamic applications

O-rings are used as both dynamic and static seals. Lids, flanges and covers are common examples of static applications. Valves, taps and fittings are examples of dynamic applications.

The O-ring is also a key sealing component as an activator in hydraulic equipment, but it is NOT recommended that O-rings be used alone as the sole sealing component in dynamic applications with continuous reciprocating (linear) piston motion or continuous rotating shaft motion.

O-rings in static applications

O-rings can be clamped axially and radially in static applications. Installation and retention in dovetail and triangular grooves are also common solutions.

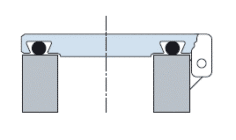

O-ring mounted axially

The O-ring is clamped axially

in the groove, in the same way

as a flat gasket.

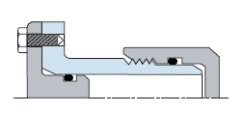

O-ring mounted in dovetail groove

In a dovetail groove, the O-ring is held in place during use. This is a great advantage when it comes to

applications that are frequently

disassembled/opened.

O-ring mounted radially

The O-ring is clamped radially

between the inner diameter [IDS] and outer diameter [ODS] of the track.

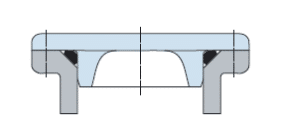

O-ring mounted in triangular groove

This installation is both

safe, inexpensive and easy to use.

O-rings

Find out more about installing O-rings and dimensioning O-ring grooves, among other things.

Pressure, temperature and media guide your choice of sealing material

Pressure, temperature and the nature of the medium are the most important factors when deciding which rubber type the O-ring should be made of?

The most common rubber types for O-rings are:

NBR

Acrylonitrile Butadiene Rubber

NBR has good sealing properties and good resistance to hydraulic oil, diesel oil and mineral grease. As NBR does not tolerate ozone or UV irradiation, it is not recommended for outdoor use. NBR is a very gas-tight material and is therefore used for gas applications.

Trademarks: Nitrile, BunaN®

Temperature range: -30 °C to +100 °C *)

HNBR

Hydrogenated Nitrile Butadiene

HNBR is an improved version of NBR, being more resistant to ozone, weather and heat. The elastomer has good sealing properties and good resistance to hydraulic oil, diesel oil, mineral grease and oil additives.

Temperature range: -40 °C to +150 °C,

briefly 180 °C *)

EPDM

Ethylene Propylene Rubber

EPDM rubber has good settling properties, good weather resistance and good resistance to many organic liquids, acids and alkalis. EPDM is also resistant to water and water vapor, but is not suitable for mineral oil or grease.

Temperature range: -55°C to +130°C *)

FPM

Fluoroelastomer

FPM has excellent resistance to mineral oils, aliphatic, aromatic and chlorinated hydrocarbons, concentrated acids, dilute acids and a wide range of chemicals.

Brands: Viton®

Temperature range: -15 °C to +200 °C *)

SWOT

Per fluoroelastomer

This material is the ultimate in elastomers for use with chemicals and high temperatures. FFPM can be explained as a material with the chemical resistance of PTFE and the setting properties of FPM (Viton®). Due to the material's chemical and temperature resistance,

FFPM is the elastomer that is best suited for long-term use in oil refineries, the pharmaceutical industry, the chemical industry and the semiconductor industry.

Trademarks: Perlast®, Kalrez®, Chemraz®

Temperature range: -15 °C to +330 °C *)

TFE/P

Tetrafluoroethylene Propylene

TFE/P is a unique fluoroelastomer that is especially

distinguished by good vapor resistance. TFE/P also has good chemical resistance to oil-strong acids and bases. In addition, the material is particularly suitable for electrical insulation.

Trademark: Aflas®

Temperature range: -10 °C to +230 °C,

briefly 250 °C *)

ETP

Ethylene / Tetrafluoroethylene / Perfluoromethylvenyl ether

ETP is a peroxide vulcanized blend of Ethylene, Tetrafluoroethylene (TFE) and Perfluoromethylvenylether (PMVE). ETP is particularly suitable for use in the petrochemical industry, where today's fuels are blended with additives such as MTBE, TAME, ETBE, toluene and alcohol. The elastomer is also resistant to polar solvents, oil, strong acids and bases. ETP is often used as a replacement for TFE/P, as the material ETP is often cheaper and more chemical resistant.

Trademarks: Kemex™

Temperature range: -20 °C to +206 °C *)

Q

Silicone

This elastomer is suitable for both high and low temperatures and has low permanent deformation. However, due to its poor tear resistance, abrasion resistance and tensile strength, the material should only be used as a static seal. Silicone is resistant to sunlight, ozone, oxygen, UV light and dry heat. Silicone is not resistant to most petroleum-based liquids or ketones, such as MEK and acetone, water vapor and ether. Silicone is not gas-tight. Silicone is tasteless, odorless and completely non-toxic. Silicone is also resistant to bacterial and fungal growth.

Temperature range: -60 °C to +200 °C *)

FVMQ

Fluorosilicone

This fluorine-modified silicone elastomer has most of the properties of silicone, but the oil and fuel resistance is significantly better. It also has good resistance to sunlight, ozone, oxygen, UV light and dry heat. The disadvantages are that the material is not gas-tight, has a low breaking strength and poor tear and abrasion resistance.

Temperature range: -60 °C to +200 °C *)

CR

Chloroprene rubber

CR has good setting properties and good

resistance to sunlight, ozone, oxygen and weathering. The material is therefore recommended for outdoor use. It is also resistant to mineral grease and some types are resistant to f reon. Less good resistance to hydraulic and diesel oil.

Brands: Neopren®

Temperature range: -30 °C to +90 °C *)

We are ready to advise you

If you didn't find what you were looking for, we're ready to help you find the right solution. The products on these pages are examples from our almost limitless universe of possible product solutions.