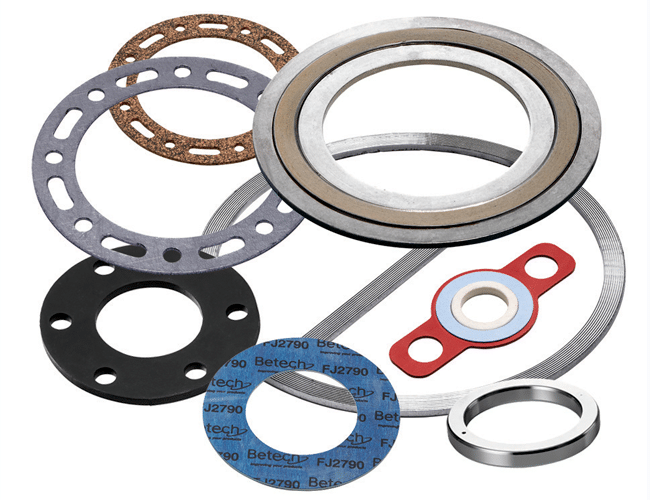

Braided gaskets

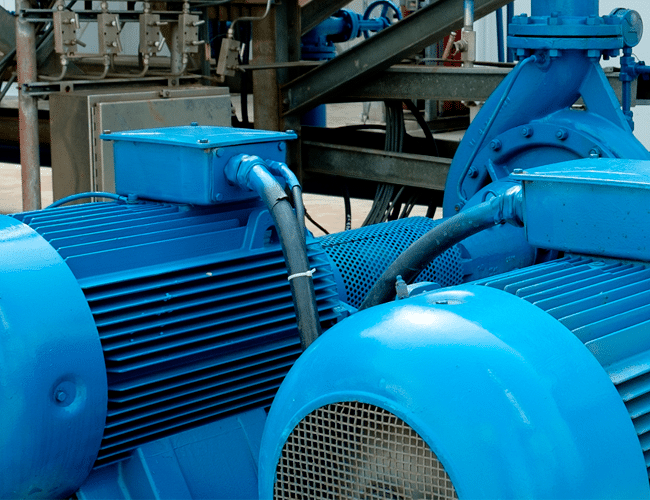

The braided gasket - also known as braided packing ring, braided cord, packing cord, water pump gasket, valve gasket and stuffing box gland packing - is an indispensable seal for dynamic applications such as pumps, valves and other rotating equipment in industrial process plants.

The braided gasket is designed to seal between the shaft or spindle and the fixed pump housing or stuffing box to prevent leakage of liquids and gases.

Main types of braided gaskets

There are several types of braided gaskets, each with their unique properties, applications, advantages and disadvantages. Here are some of the most common:

Graphite

Braided gasket with graphite yarn

These gaskets are known for their high temperature and pressure resistance. They are ideal for use in extreme environments where other gasket types may fail.

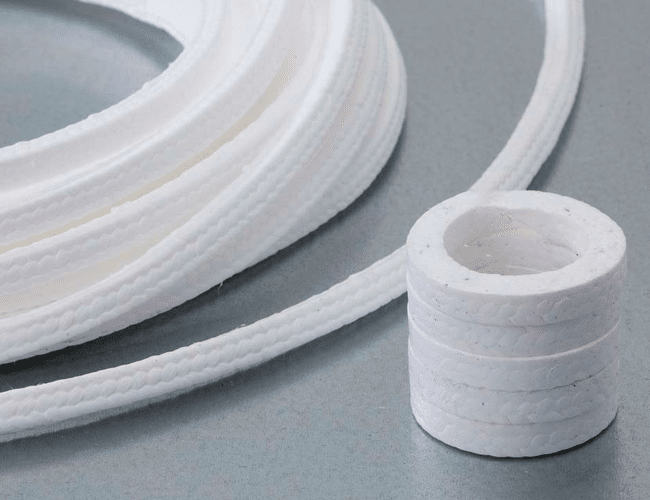

PTFE

Braided gasket with PTFE yarn

PTFE, or polytetrafluoroethylene, is a material known for its chemical resistance. These gaskets are ideal for use in chemical processes where they can withstand aggressive media.

ARAMID

Braided gasket with aramid fibers

Aramid is a strong and durable material that is ideal for use in high-pressure applications. These gaskets are known for their durability and long service life.

Where are braided gaskets used?

Braided gaskets are used in a wide range of industries and applications. Here are some of the most common:

Energy & utilities

In power plants, heating plants and other energy production and distribution facilities, braided gaskets are used to seal pipes and hatches (static application), valves and pumps (dynamic application) and other systems with liquids and gases under high pressure and temperature.

Food industry

Braided gaskets, especially the PTFE type, are safe to use in food production as they are resistant to bacteria and other microorganisms.

Chemical industry

Due to their chemical resistance, braided gaskets are often used in chemical processing plants where they can withstand aggressive media.

Know the benefits and limitations of braided gaskets

Braided gaskets are a common seal type in many applications in industrial process plants, cargo pumps and transportation augers. It is important to understand the different types, their applications, as well as their benefits and limitations.

braided gasket - Benefits

- Temperature and pressure resistance

Braided gaskets can withstand extreme temperatures and pressures, making them ideal for use in demanding industrial environments. - Chemical resistance

Many types of braided gaskets are resistant to a wide range of chemicals, making them ideal for use in chemical processes. - Durability

Braided gaskets are known for their durability and long lifespan, which can reduce maintenance costs and downtime in many industrial processes.

braided gasket - limitations

- Installation

Braided gaskets require professional installation to ensure they function properly. This can increase the overall cost. - Price

Some types of braided gaskets, especially those made from specialized materials like PTFE or graphite, can be more expensive than simpler gasket types. - Not suitable for all applications

Although braided gaskets are very versatile, they are not suitable for all applications. For example, they are not always the best choice in highly corrosive environments or where there is significant abrasive wear (material degradation particles).

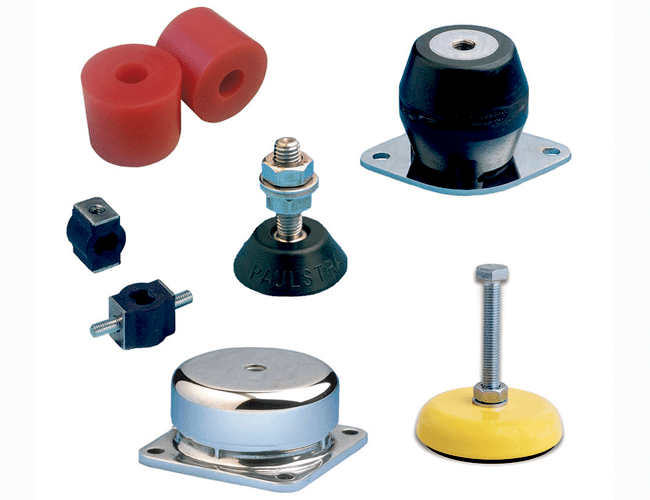

We help you get the job done

Whether you are a manufacturer or in service and repair, we can help you find the optimal solution for your project. We pride ourselves on solid and solution-oriented advice, and with a strong product range based on several renowned manufacturers, you'll never go wrong with Betech.

Overview: Latty braided gaskets

Braided gasket with graphite - LATTYgraf T

Braided gasket (shaft seal) made from 100 percent pure and continuous graphite yarn, impregnated with a graphite mixture.

Very low coefficient of friction, good heat dissipation and excellent elastic recovery. Suitable for high speed.

PH values for media: 0 to 14. Working temperature: -200 to 600 °C.

Braided gasket with PTFE - LATTYflon 3206

Braided gasket (shaft seal) made from 100 percent PTFE silk yarn, where each individual yarn is impregnated with PTFE.

The gasket is further impregnated with a mixture of PTFE and sluggish lubricant during the braiding process.

PH values of media: 0 to 14. Working temperature: -200 to 280 °C.

Braided gasket with aramid - LATTYflon 4788

Braided gasket (shaft seal) made from 100 percent aramid fibers. Each yarn is impregnated with PTFE using a unique "Filcoat" process. Then further impregnated with a mixture of PTFE and food-grade quality lubricant.

Very high mechanical performance. PH values for media: 2 to 13. Working temperature: -220 to 300 °C.

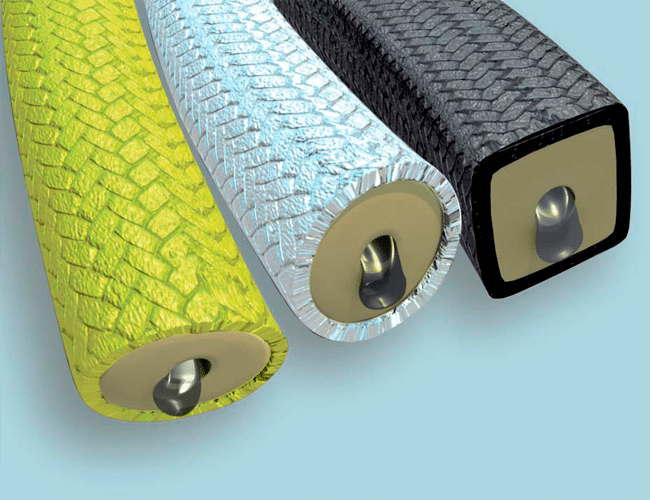

Mixed yarn braided packing - LATTYflon 4757

A very strong multi-yarn gasket (shaft seal). The corners are made of 100 percent aramid yarn impregnated with PTFE. The lubricated friction surfaces are made of 100 percent graphitized PTFE yarn. The entire seal is further impregnated with a mixture of PTFE and a lubricant.

Combining the benefits of graphite, PTFE and aramid, this gasket achieves high mechanical abrasion resistance.

PH values for media: 2 to 14. Working temperature: -220 to 300 °C.

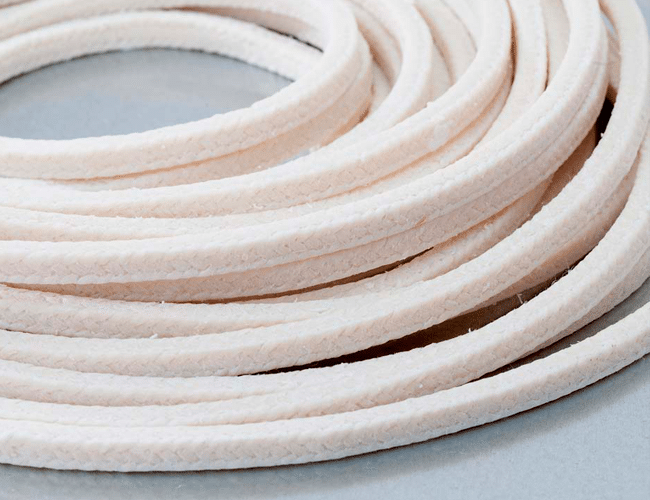

Vegetable yarn braided gasket - LATTYflon 1779

A plant-based packing cord (shaft seal) made from high-quality ramie yarn (Boehmeria nivea) with anti-rot treatment.

Impregnated with a mixture of PTFE and lubricant during the braiding process.

PH values for media: 4 to 11. Working temperature: -40 to 120 °C.

Overview: LubSeal braided gaskets

Flexible braided gaskets - LubSeal

A plant-based packing cord (shaft seal) made from high-quality ramie yarn (Boehmeria nivea) with anti-rot treatment.

Impregnated with a mixture of PTFE and lubricant during the braiding process.

PH values for media: 4 to 11. Working temperature: -40 to 120 °C.

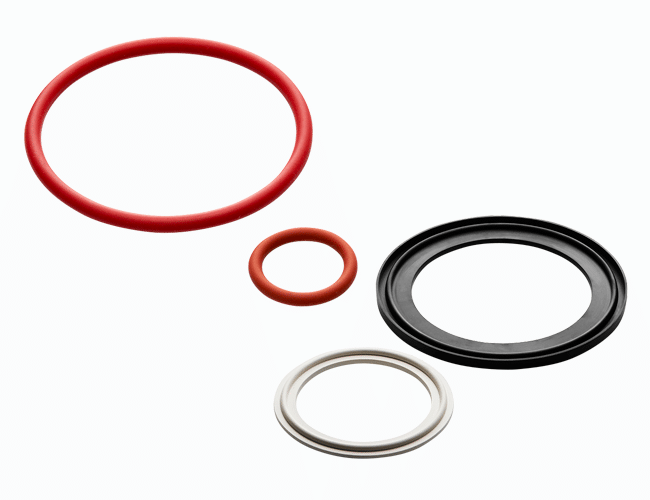

Elastomer core:

choose between EPDM / NBR / Silicone, each in 5 different hardnesses (Shore A).

Braided cape:

choose between 3 different fiber materials: Aramid / Polyamide / PTFE.

Lubrication/Impregnation:

choose between graphite, PTFE or none (dry).

With the options of cores, fiber materials and lubrication, it's possible to configure a unique, customized sealing solution.

The flexible, braided gasket is supplied as pre-formed rings. Different sealing profiles are also possible.

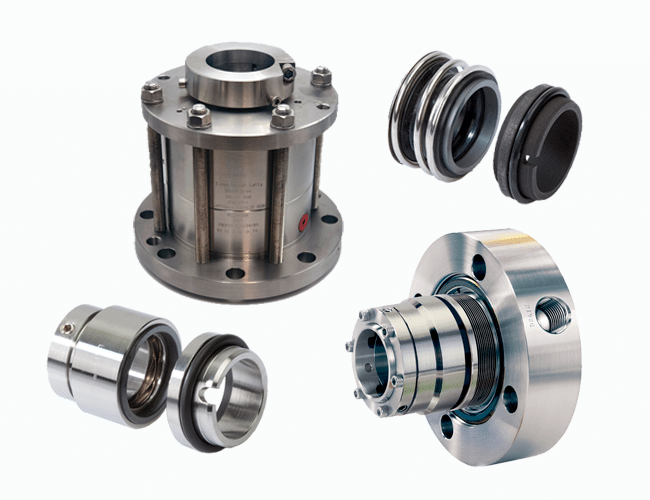

Sealing solutions for rotating equipment

Complete range of high-end quality mechanical shaft seals (agitator and cartridge seals, pusher, split and bellow seals) and braided gaskets for both manufacturers (OEM) and service companies (MRO) - with associated experienced technical support.