Automation and Robots

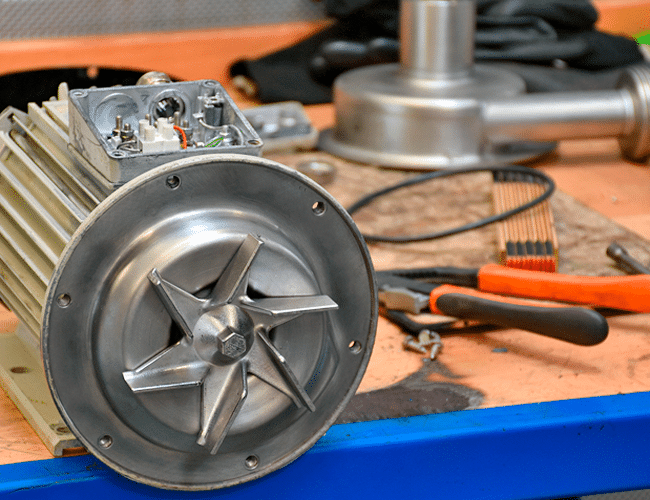

Durable protection and seals for mechanical equipment

In a constantly evolving world, automation and industrial robots have become an indispensable part of the industrial landscape. These technologies are essential for maintaining competitiveness and efficiency in many sectors, including manufacturing, logistics and service industries.

PRECISE AND CONSISTENT PRODUCTION

Industrial robots are designed to perform repetitive tasks with high precision, consistency and complexity in dynamic environments such as assembly, packaging, welding or soldering, spray painting and inspection.

There are several critical factors that OEM manufacturers, suppliers and service companies must consider when developing, producing and configuring automation solutions.

Speed and precision are essential to perform tasks efficiently. The ability to integrate with other systems and technologies such as the Internet of Things (IoT) and Artificial Intelligence (AI) is crucial for the flexibility and versatility of the equipment.

Finally, robustness and durability are also important. Automation must be able to withstand demanding working conditions and ensure a good return on investment with a long lifetime. This requires high quality in both design and manufacturing, as well as regular maintenance and service.

Polymer products are key components

Ultimately, the success of automation and industrial robots relies on a combination of advanced technology, skilled engineering, durable quality components and proper maintenance.

Betech is the ideal partner and supplier of polymer-based components for your automation equipment.

Machine gaskets and static seals

Flat machine gaskets and static seals are essential to ensure that robotic and automation systems can operate efficiently and safely. The following properties can be critical:

Durability: Gaskets and seals must be able to withstand the conditions given by the technical design and the equipment's working environment - such as high temperatures, pressure and corrosive materials.

Accuracy: Gaskets must fit precisely to ensure optimal performance and prevent leakage or ingress of harmful particles.

Compatibility: The seals must be resistant to the materials and any liquids they come into contact with.

Dynamic seals

Dynamic seals are used in and between parts that turn, rotate or have a linear movement in relation to each other. They must be able to withstand wear and movement over time. The following properties can be critical:

Flexibility: Seals must be flexible enough to allow movement, but robust enough to resist wear and tear.

Durability: The seals must be able to withstand long-term use without losing their sealing properties or other functionality.

Accuracy: Seals must fit precisely to ensure optimal performance and prevent leakage or ingress of harmful particles.

Molded rubber and silicone parts

Molded technical rubber parts are used in many different parts of robots and automation, typically in moving parts or in structures. Critical factors can be:

Strength: The rubber part must be strong enough to withstand the forces it is exposed to.

Durability: The rubber part must be able to resist wear and aging.

Compatibility: The rubber part must be compatible with the other materials it comes into contact with.

Vibration dampers and machine feet

Vibration dampers and machine feet can be included in automation equipment to control and minimize vibration and noise. They also help protect the floor and other surfaces. Critical factors include:

Efficiency: The damper effectively absorbs vibrations and noise.

Durability: The damper must be able to withstand long-term use without losing its damping properties.

Stability: The damper must be stable and dimensioned correctly so that the equipment is stable and safe during operation.

Want to HEAR WHAT WE CAN DO FOR YOUR BUSINESS?

Betech offers powerful, versatile solutions for the needs of the automation industry.

Cases from different industries and applications

Our aim is always to create added value for our customers. With one or more creations that improve your product, machine or plant - and perhaps enable a new, innovative idea?

See selected customer cases with examples of product solutions that show how Betech is practicing the mission, Improving your productsin a wide variety of applications and industries.

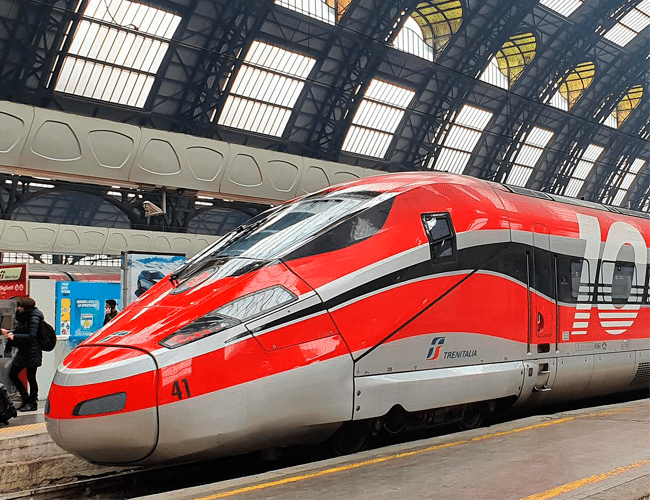

Energy/supply

Large and stable cam profile: Faster installation and longer service intervals