Foodtech

Food, ingredients and dairy production

Industrial equipment for processing meat, fish, poultry, vegetables, fruit and grains - food processing equipment - plays a crucial role in food production and processing. The equipment is designed to optimize efficiency, ensure quality and increase production capacity.

Critical factors for food equipment

What key elements should OEM manufacturers, service and maintenance companies be aware of when designing, repairing and rebuilding equipment for the food industry?

Robustness, durability and performance

Machines must withstand high production volumes and constant use, often in harsh environments. Stainless steel and other durable materials are typically chosen for their ability to resist wear and corrosion. The machines must handle food with high precision and consistency. This requires advanced control and guidance systems in addition to precision components.

Product safety and hygiene

Machine parts and components that come into contact with food must meet applicable industry standards or regulations and have the necessary approvals.

The equipment must be easy to clean and maintain to prevent bacterial growth and cross-contamination.

A good design minimizes dead zones and makes it easy to disassemble components for thorough cleaning.

Energy and cost efficiency

With rising energy prices and increased focus on sustainability, manufacturers are continuously looking for ways to reduce energy consumption. This can be achieved through innovative design solutions such as energy-efficient motors and heat recovery systems.

An initial outlay for high-quality machinery and equipment can be significant, but the long-term savings in terms of increased productivity, reduced downtime and lower maintenance costs can make it a sound, worthwhile investment.

When machine builders and service companies meet these stringent requirements and industry standards, they deliver the highest value to their customers.

Product solutions that meet all standards and requirements in the food industry

Do you want to avoid spending time and costly misinvestments on components that don't meet the requirements of the food industry anyway?

Betech offers manufacturing conditions and product solutions in materials that meet standards, approvals and regulations on three continents. These include approvals and standards for food contact materials (FCM) and drinking water applications or the sanitary standards often required in process equipment and manufacturing plants.

Foodstuff

- BEK 681 (DK)

- BFR XV

- BFR XXI

- BSE/TSE

- COS-PS

- DGCCRF

- EU 2023/2006 GMP

- EU 10/2011

- EU 1935/2004

- FDA Title 21

- GB 31603-2015 GMP

- GB 4806.1/6/11 2016

- GB 9685-2016 A1/A3

Drinking water

- ACS XP P 41-250

- BEK 1007 (DK)

- KTW-BWGL - for plastics

- KTW-BWGL (UBA) - for elastomers

- W-270

- W-534

- WRAS (WRC)

Bio/Pharma/Sanitary

- USP 26 Class VI

- ISO 10993-1

- NSF 51

- NSF 61

- 3A 18-03

- EN 681-1

Smiley - food inspections

Betech stores and handles materials that may come into contact with food in end-user applications. Therefore, Betech is subject to the Danish Veterinary and Food Administration's "Smiley" inspection scheme.

See food inspection results and Betech's last four inspection reports.

Make your equipment better with products from Betech

In the food industry, the right choice of gaskets, seals, technical rubber parts as well as vibration dampers and machine feet can be crucial for reliable operation and safe product quality.

Industrial gaskets

Industrial gaskets are essential to ensure tightness in different parts of food equipment.

In pumps and valves, industrial seals prevent leakage of liquids and gases, ensuring efficient and safe operation.

In heat exchangers, they ensure there is no cross-contamination between different fluids passing through the equipment.

Static seals

Static seals are used (like gaskets) in situations where the sealing surfaces are fixed in relation to each other. They ensure that no leakage occurs during operation.

In pressure vessels, the seal prevents leakage under high pressure and temperature.

In pipe connections to prevent the escape of liquid, steam or gas, O-rings and especially Clamp seals are popular due to easy disassembly when cleaning the piping systems.

Dynamic seals

Dynamic seals are used in machine parts that move in relation to each other and ensure that no leakage occurs during movement.

In rotating equipment such as pumps and mixers, mechanical shaft seals or braided packing rings ensure that no leakage occurs during rotation.

In hydraulic and pneumatic cylinder systems, piston and rod seals prevent leakage of liquids or gases.

Rubber and silicone moulded parts

Rubber and silicone molded parts are widely used in food production and processing equipment due to their characteristic abrasion resistance and elasticity.

In conveyor belts and other handling equipment, molded rubber parts help absorb shock and minimize wear and tear.

In pumps and valves, they can provide flexible connections and seals that resist pressure and temperature changes.

In the form of hoses or flexible tubes, rubber parts can be used in fluid and media transport applications.

Vibration dampers and machine feet

Vibration dampers and machine feet minimize noise and vibrations from pumps, mixers and other vibrating machinery.

They improve the physical working environment, stabilize machinery and extend equipment life by reducing wear and tear and absorbing pressure and shock.

They are especially important in high-speed and high-volume production lines, where even minor vibrations can have a significant impact on product quality and equipment lifespan.

High quality products and service

It's important to us that you receive high-quality products and advice. That's why we have the ISO 9001:2015 quality management system, which covers product design, production and service.

We perform measurement reports on critical dimensions and produce according to ISO 3302-1 (Tolerances for rubber and silicone products), DIN 7715-5 (tolerances for rubber stamped and cut parts), DIN 61206 (tolerances for needle felt/wool felt) and GKV tolerances for PTFE/plate materials. Finer tolerances can usually be met upon request.

Want to know more about our solutions for the food industry?

Would you like to hear about the products we've helped develop or improve at other companies in the food, dairy and beverage industry?

Cases from different industries and applications

We always aim to create added value for our customers. This happens with one or more creations that improve your product, machine or plant - and perhaps enable a new, innovative idea?

See selected case studies with examples of product solutions that show how Betech is practicing the mission, Improving your productsin a wide variety of applications and industries.

Process Industry/Foodtech

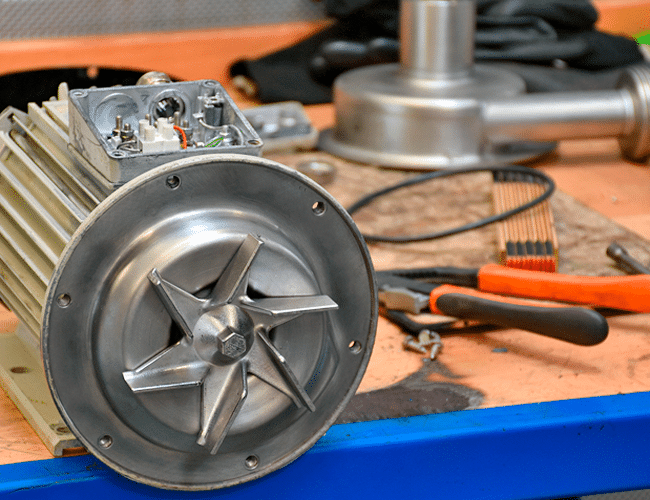

Repair your pump - it's good for the environment and your wallet

Energy/utilities

Large and stable cam profile: Faster installation and longer service intervals