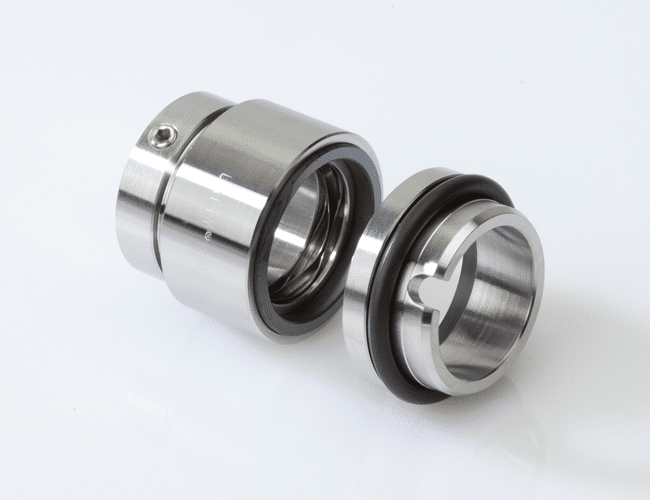

Mechanical shaft seals

Mechanical shaft seals provide a unique sealing system for rotating equipment in challenging environments where conventional seals, which seal around the shaft or spindle by compression and the more or less permanent springback of the gasket material, do not provide sufficient sealing in the most challenging applications or only maintain a satisfactory seal for a limited time.

Mechanical seals are often used here

Mechanical seals - or heavy duty seals - are used in pumps, augers, agitators and mixers and are therefore found in various industries such as food processing, chemical and pharmaceutical processing, biogas, sludge and wastewater plants, as well as in equipment and machinery for heavy, particulate mineral extraction and material transportation.

Several types of mechanical seals

By choosing the right type and configuration, mechanical shaft seals - even in the most demanding circumstances - can prevent leakage of liquids or gases to the environment and ensure reliable operation and efficient production.

pusher seal

Pusher seals or carrier seals are a popular type of mechanical seal known for their robustness and damping ability.

They feature a spring in combination with movable secondary elastomer seals such as O-rings, making them ideal for use in high pressure and high speed areas.

Metal bellows seal

Metal bellows seals are another type of mechanical seal designed to handle extreme environments and temperature ranges.

They have no moving secondary seals and achieve their flexibility via edge-welded plates. Metal bellows seals are suitable for large axial movements, especially at high temperatures.

Component sealing

Component seals or rubber bellows se als consist of a loose rotating part and a loose stationary part, making them more complicated to install than cartridge seals.

Still, they are widely used in many industries and often the preferred type in OEM pumps.

Cartridge seal

Cartridge seals are designed to be easy to install. Unlike component seals, which consist of separate parts that need to be assembled when installing the seal, cartridge seals come as a single unit that can be mounted directly onto the shaft without any additional adjustments.

The risk of installation errors is minimized, making the cartridge seal a popular choice in many industries.

Patron seals can be of different types, including single, double, and multi-spring designs, and made from different materials, which are selected for the specific application conditions.

agitator/mixer seal

Mixer, agitator or stirrer seals ensure reliable and continuous operation in stirring and mixing systems, sorting and filtration drums, etc. where raw materials and ingredients need to be mixed or raw materials need to be separated, dried, etc.

The design can handle large movements and impacts both axially and radially.

In addition to the types mentioned, mechanical shaft seals are sometimes also referred to as process seals, spring seals, rotary seals, shaft seals or heavy duty seals.

We help you get the job done

Whether you are a manufacturer or in service and repair, we can help you find the optimal solution for your project. We pride ourselves on solid and solution-oriented advice, and with a strong product range based on several renowned manufacturers, you'll never go wrong with Betech.

Product overview - Mechanical seals

Rubber bellows and component seals - LATTY

Rubber bellow seals and component seals are recognized and preferred types of mechanical seals for OEM pumps.

Universal types for use in all kinds of pumps with a standard shaft, not sensitive to shaft deflections.

Available in many material combinations and a wide range of dimensions.

Meets multiple approvals and standards.

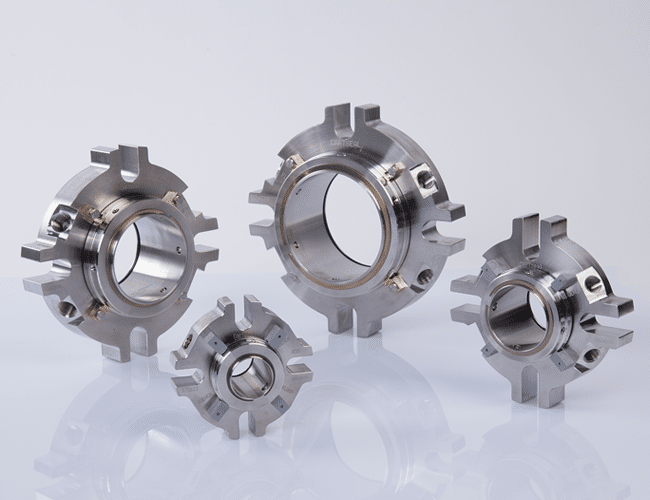

Carrier seals - LATTY

Pusher seals are universal for most rotating applications including food production equipment. Some types are additionally designed to work with media containing solids.

The carrier type is independent of the direction of rotation and is available in a range of sizes and different material combinations. In some types, the steel spring is protected from the media.

For use in high pressure applications up to 25 bar and with a balanced carrier seal up to 40 bar.

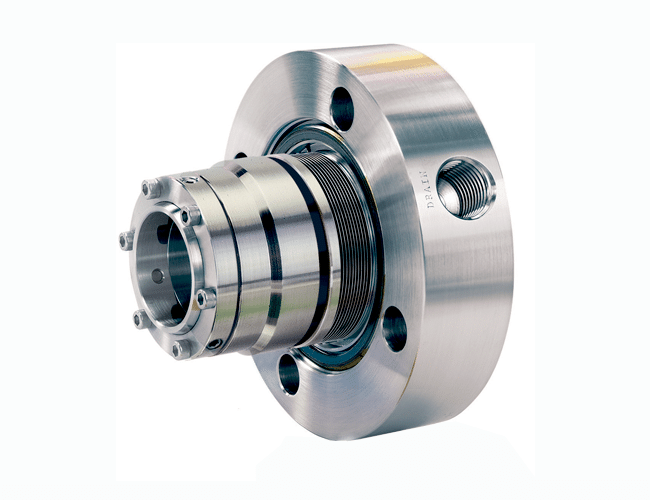

Front seals - LATTY

Cartridge seals are a balanced seal type, independent of direction of rotation, and manufactured as single or double seals. Double cartridge seals have an integrated pump function that circulates coolant and lubricant.

Patron seals are available in different sizes and material combinations and are ideal for standardization and new development projects.

Maintenance and service checks are easily carried out on this seal type, allowing you to extend its lifespan. Cartridge seals are also suitable as a replacement for braided gaskets.

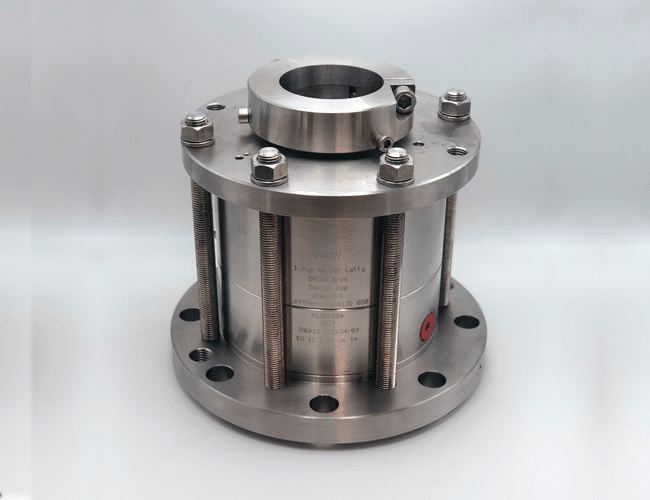

Agitator seals - LATTY

Agitator/mixer seals are mechanical shaft seals that are independent of direction of rotation and are manufactured as single or double seals. Available with or without bearings, they are suitable for top entry drives, bottom drives and side-mounted drives.

An optional barrier fluid system can be connected for efficient cooling and continuous lubrication.

Ready to install according to drawing and delivered as a factory tested unit. Can be manufactured and delivered in different sizes.

Metal bellows seals - Flexaseal

Edge-welded mechanical metal bellow seals for both low and high temperature (temperatures up to 425°C) and working pressures up to 20 bar.

This type of hydraulically balanced metal bellows seal is self-cleaning by centrifugal force and therefore a good choice for slurry and other particulate media.

Patron seals - Flexaseal

Flexaseal cartridge seals are available in different types: single and double cartridge, single or multi-spring solutions and metal bellows types.

In addition, combinations of soft/hard as well as hard/hard sealing surfaces are possible, also sealing surfaces with perflouro-elastomers (FFKM) are possible.

API approved.

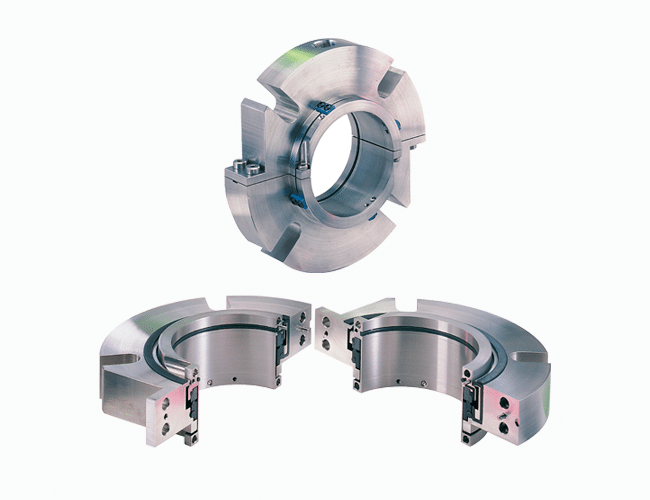

Split seals - Flexaseal

Style 85 split cartridge seals are extremely easy to install and significantly reduce downtime in challenging and time-consuming installations.

No need for measuring, special tools, shims or adhesives.

No other split design divides the cartridge sealing kit into just two integrated parts and makes handling and installation as simple as this product line from American Flexaseal.

The only split seal that is fully assembled and pressure tested at the factory.

Cooling and lubrication systems - Flexaseal

Cooling/lubrication and Barrier liquid supply systems are used in conjunction with dual cartridge sealing configurations.

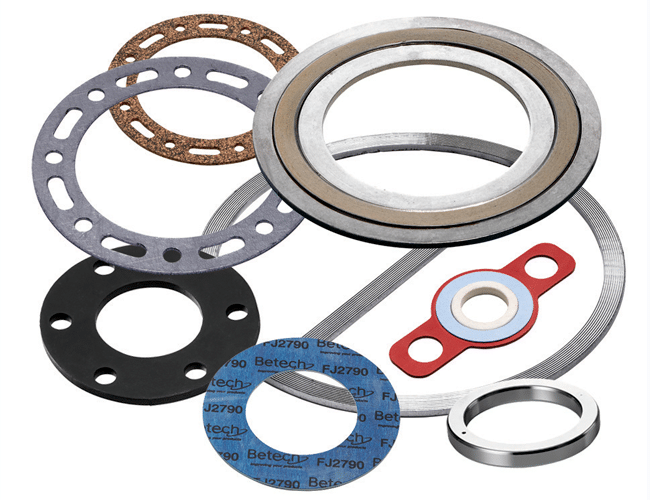

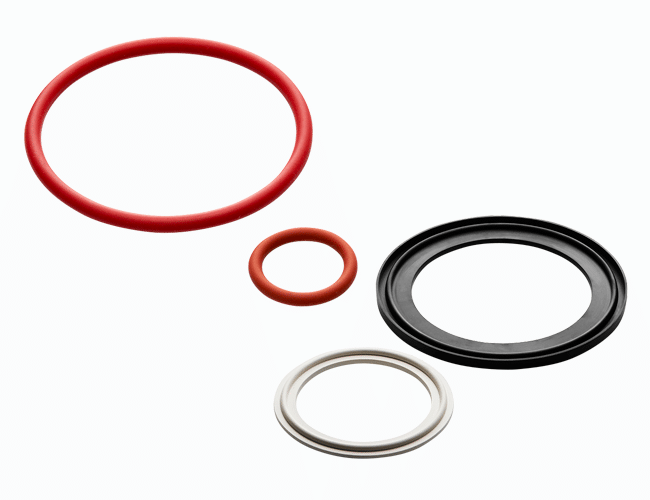

Sealing solutions for rotating equipment

Complete range of high-end quality mechanical shaft seals (agitator and cartridge seals, pusher, split and bellow seals) and braided gaskets for both manufacturers (OEM) and service companies (MRO) - with associated experienced technical support.