- Material: PTFE, Production

PTFE insulation sheet is cut with a thin water jet

Cutting ptfe board for cabling and mounting electrical equipment: An insulation board for use in infrastructure projects comes into being. This is what happens in Betech's production hall ...

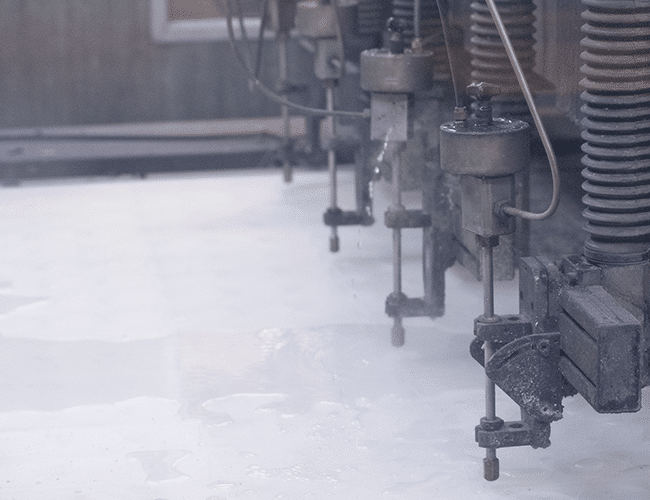

Precision cutting with waterjet

This PTFE sheet turns into a practical product used for cabling and mounting electrical equipment in tunnels, ships, construction, manufacturing facilities and more.

The precision cutting of the product can be done both with an oscillating knife on a flatbed cutter and on a waterjet system with paper-thin water jets from four high-pressure nozzles.

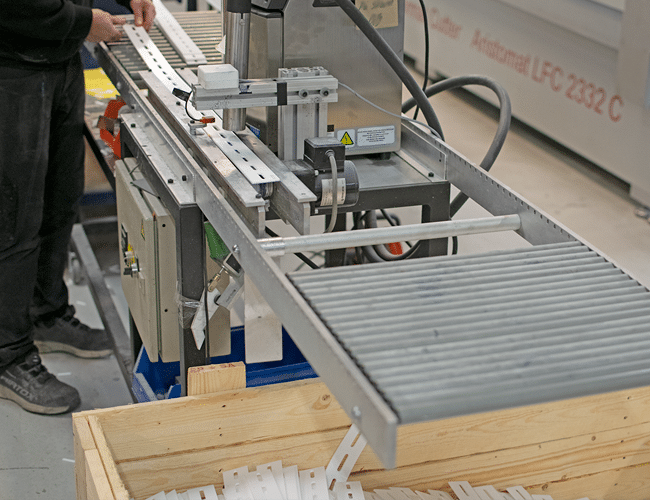

ID number printed on the item

The customer ID number is printed directly on the finished product as part of efficient logistics and quality assurance all the way to installation at the point of use.

Control measurements are taken throughout the process. And 1 - 2 - 3 ... the product is ready to be packed and delivered.

Betech is best known for quality solutions in gaskets, seals, molded rubber parts and vibration dampers. But we supply many other polymer-based products.

Are you curious about what else Betech can produce at the factory near Esbjerg? Find out more here:

Water cutting of PTFE sheet with four high-pressure nozzles.

Inkjet print of the customer ID number on the finished item.

Betech is best known for quality solutions in gaskets, seals, molded rubber parts and vibration dampers. But we supply many other polymer-based products.

Contact us if you're curious about what else Betech can produce at the factory near Esbjerg?