Sealing in extreme conditions

It may seem like a small thing - seals. But in fact, seals are just as important as the machine's engine. Therefore, the choice of seals for your machinery and technical installations should be carefully considered. If the application needs to seal under extreme conditions such as high, sustained pressure, very low - or high - temperatures.

- Seals

Avoid costly machinery and plant breakdowns

It may seem like a small thing - seals. But in fact, seals are just as important as the machine's engine when it comes to reliability and stable operation without fatal breakdowns.

At Betech, we pride ourselves on our expertise and specialized knowledge of seals - and not least to be able to offer you one of the best of its kind, Astra Seal® - a seal so effective that even NASA uses it in their space rockets. Of course, smaller can do it too, and we can help you find the best solution for your machinery and plant.

Does the company's machinery work in aggressive environments?

Then you know that it wears the seals and can cause animal downtime. That's why it's a good idea to invest in seals that are designed to withstand the effects of aggressive substances and solutions.

AstraSeal® seals excellently in aggressive environments. This makes it unbeatable for storage tanks, freezers, compressors, cold boxes, heat exchangers, steam systems, pumps and valves:

- Cryotechnical facilities

- AeroSpace industry

- Beverage and food production

- Petrochemistry

- Pharmaceutical production

Do you need your seal to work in very cold conditions?

Finding a seal that can withstand extreme temperature conditions is difficult. The extreme temperatures will soften and degrade the seal - and if it's not suitable for the conditions, leaks will occur, which can result in downtime or injury.

With Astra Seal® you get seals that withstand temperatures from -250°C to +260°C.

That's why it was chosen by a well-known industrial gas company for an environmental project in the transportation sector where liquid nitrogen is transferred under very low, cryogenic temperatures. Ordinary elastomer seals fail at such low temperatures, while AstraSeal® holds tight.

If you also want to avoid having to replace seals from time to time, Astra Seal® is a sensible choice.

Is your application exposed to high pressure and extreme temperature?

Choosing the right seal is crucial for the reliability of machinery operating at very high pressures. An insufficient quality seal can lead to leaks, increased wear and unplanned downtime, which both reduces the lifetime of the machine and increases maintenance costs.

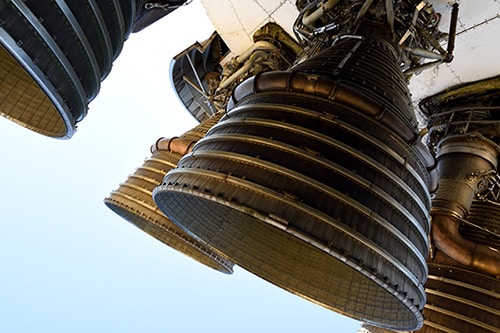

By choosing a seal designed for the demanding pressure conditions, you ensure stable operation with minimal risk of failure. For the same reason, NASA has used Astra Seal® for the lifting systems in several Saturn rockets, as well as the external propellant tank and main engine of the space shuttles. The Astra seal withstands both the repeated pressure cycles and temperatures well below freezing.

Are you looking for a seal that can withstand high pressure and extreme cold? Then you should learn more about what AstraSeal® can do for your products.

Your guarantee for optimal solutions

At Betech, our mission is to optimize your products, machines and production facilities. That's why we are proud to have Astra Seal® as part of our product catalog.

Our advice is always based on your specific application and the prevailing application conditions. This ensures you optimal solution choices in gaskets, seals and technical polymer products.