The competent partner

for OEMs and machine builders

High demands are placed on the quality management of the machine builder or OEM's products. At Betech, we are the perfect partner for your OEM company because:

- We have detailed knowledge and extensive experience in gasket materials, rubber molding, sealing and application technology

- Our specialists provide technical support to the company's development department and engineers

- We support the need for documented quality management

Knowledge that makes your products even better

As a machine builder or OEM manufacturer, it's difficult to have detailed knowledge of all the components in your products. At Betech, we have specialized knowledge of seals, industrial gaskets, molded rubber parts made of high-performance elastomers and other polymer-based products. This means that as a partner to your OEM company, we can:

- Advise on which material best suits your needs

- Help optimize your product

- Custom-made solutions that fit your products perfectly

We have a long tradition of providing technical advice to OEM companies. You can read some examples of solutions we have created that have added value for OEM customers in all branches of industry.

Solutions that meet all industry standards

Are there any special requirements for the materials in your products?

As a partner to many different OEMs, for example, we know what materials are needed:

- suitable for contact with food or drinking water

- are suitable for oils, acids or basic media

- Suitable for low or high operating temperatures

- can withstand harsh environments and aggressive influences

- meets relevant fire ratings

Our specialists know the requirements and standards of your industry. As an OEM partner, we can always help you find a solution that meets these requirements.

Documented quality management

At Betech, we know how important it is for your business that high quality is well documented. When you do business with us, you get well-documented quality management based on, among other things:

ISO 9001:2015

We manage quality in accordance with ISO 9001-2015, ensuring high standards in production, design and service.

Certificate of conformity

Need a declaration of conformity or material data sheet?

Betech provides documentation that the product or material meets the relevant standards and approvals.

Production tolerances

We carry out measurement reports on critical dimensions and produce according to:

- ISO 3302-1 (Tolerances for rubber and silicone products)

- DIN 7715-5 (tolerances for punched and cut rubber parts)

- DIN 61206 (tolerances for needle felt/wool felt)

- GKV tolerances for PTFE/sheet materials

We can also handle finer tolerances as needed.

PPAP and APQP

Where there are special needs, we can offer development, supply chain and production to be managed in a PPAP process. It documents that each component meets your OEM requirements. It also ensures that we, as an OEM partner, avoid costly mistakes by documenting all stages of production - from design to finished product.

Cases from different industries and applications

Our aim is always to create added value for our customers. With one or more creations that improve your product, machine or plant - and perhaps enable a new, innovative idea?

See selected customer cases with examples of product solutions that show how Betech is practicing the mission, Improving your productsin a wide variety of applications and industries.

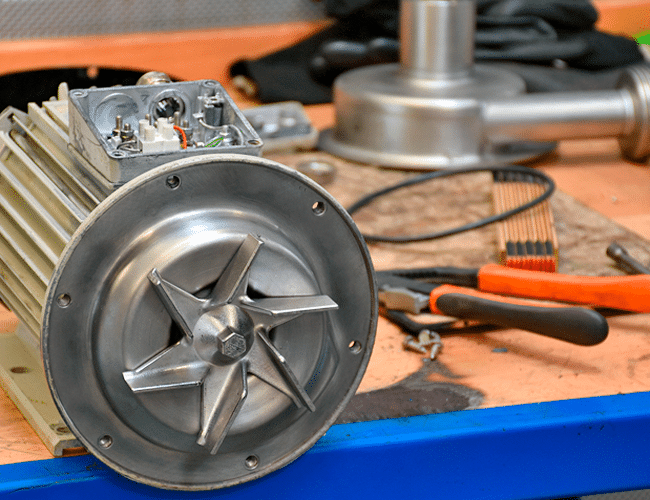

Energy/supply

Large and stable cam profile: Faster installation and longer service intervals